Start with the End in Mind

BOND’s Integrated Services model is a collaborative approach that combines the latest technology innovations with the brightest teams to manage the entire life-cycle of the project. From preconstruction to completion, BOND’s Integrated Services provide Reality Capture, Virtual Design & Construction (VDC) and MEP services to maximize value and deliver long-term Operations & Maintenance (O&M) readiness facility for our clients.

In-House Expertise

In-House Expertise

Starting in preconstruction, we visually plan any impacts to the site during construction by developing logistics plans supported by modeled renderings, 4D timeline simulations, & critical pick rigging animations. Working closely with the design team, we conduct constructability and peer reviews of the modeled elements in Revit, evaluating pinch points, cost drivers and design challenges. For renovations, our Reality Capture Team provides laser scanning services that create accurate as-built models of existing conditions including architectural, structural, and MEP/FP systems. Having an accurate point cloud and Revit model from the start, reduces the project risk for existing condition change orders in the field.

Visualize. Plan. Deliver.

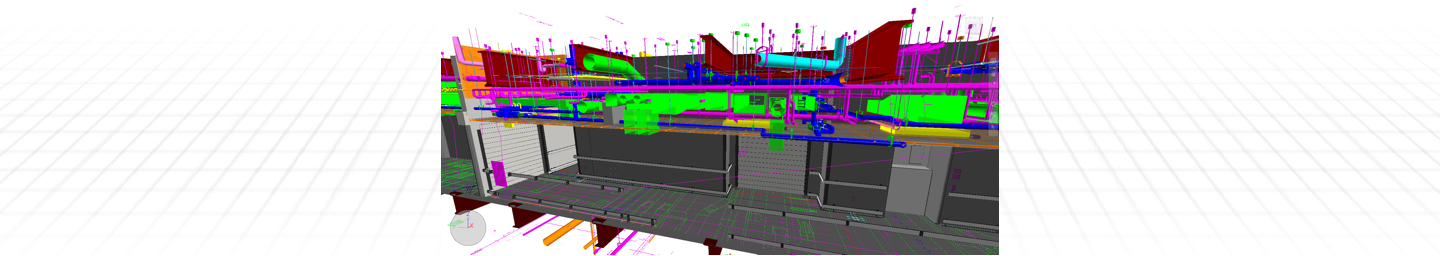

During coordination, both our VDC and MEP teams work together in a parallel path. Using BIM, the VDC team resolves spatial conflicts and constructability issues. Our VDC team is an integral part of the coordination process with the subcontractors providing solution based clash detection. We also manage a “supplemental” Revit model to enhance the detail of the coordination.

Building the Future

We believe that investing in the resources and quality of services around properly installed MEP systems is the best risk mitigation that can be done on a project. The MEP team utilizes HoloLens augmented reality, the BIM Box, and BIM 360 Field to evaluate the accuracy of installation. Our new Touch QA/QC technology provides real-time analytics and metrics of the installation to monitor the entire process.

O&M Ready from Day One

At the time of building turnover, all equipment has been validated through the design, submittal and installation phases of the project. Access zones to equipment, valves and control panels have been tracked and maintained. Key attributes for each asset, the approved submittals and the functional check-lists are organized in a comprehensive database. This asset data can be exported from our system to populate the owner’s Computer Maintenance and Management System (CMMS).

Our full range of services include:

- 3D Logistics Planning & Reviews

- Model-Enhanced Estimates

- 3D Laser Scanning & Modeling

- Drone-captured Video and Still Imagery

- Accurate As-Built Drawings

- Solution-Based Clash Detection

- Installation Accuracy Evaluation

- Advanced Schedule Simulation

- Critical Pick Planning & Animations

- Long Lead Equipment Validation

- Constructability Peer Reviews

- Touch QA/QC Technology for Real-Time Analytics

Benefits:

- Enhance Communication

- Accelerate Project Schedule

- Lower Cost

- Improve Overall Quality

- Resolve Design Conflicts

- Plan for or Maintain Equipment Access & Maintenance

- Eliminate Surprises

- Reduce Errors

- Minimize Risk